We can custom stainless steel water bottle, such as material, logo and pritning, and body shape, color.

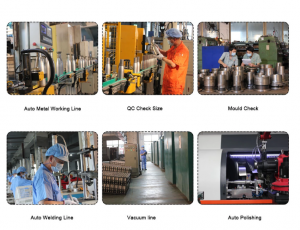

Brief description of production process

1. Pipe cutting: use a lathe, require accurate dimensions, find defective products and waste materials in time, and avoid pits, pits, pits, and scrapped products during operation.

2. Water swelling: The water swelling press requires concentration, and always pay attention to whether the pit, size and shape of the product meet the requirements.

3. Segmentation: Use an instrument car to cut off the two outer shells of the water swelling one and the other. The dimensions are required to be accurate, the cuts are uniform, no gaps, and burrs. Handle with care to avoid pits, pits, pits, and scrap Product.

4. Bulging: using a large press requires attention. The weld of the shell should correspond to the joint of the mold. Always pay attention to whether the pit, size, and shape of the product meet the requirements.

5. Rolling angle: Use a lathe to roll the two corners of the concave shape of the bulging shell to meet the size requirements, avoiding pits, pits, pits, and scraps.

6. Bottom shrinking: Use a lathe to shrink the arc bottom opening of the bulging shell to meet the size requirements to avoid pits, pits, pits, and scraps.

7. Cut the bottom: Use a lathe to cut the bottom of the shell that has been shrunk to the standard size. The cut is uniform, without gaps, and burrs. Handle with care to avoid pits, pits, pits, and scraps.

8. Reinforcement: flatten the welding seam at the shell mouth on a small press, so that there will be no skip welding during welding, so that the welding joint is smooth and even.

9. The top of the shell is flat: Use a lathe to have a uniform flat, no gap or burr, which meets the requirements, handle with care to avoid pits, pits, pits, and scraps.

10. Bottom punching: Use a press to pay attention, always pay attention to whether the pit, size, and shape of the product meet the requirements, and pay special attention to whether there are cracks at the bottom of the punch.

11. Flat-bottomed mouth: Use an instrument car, the flat-bottom mouth is even, without gaps, burrs, meets the requirements, handle with care, avoid pits, pits, pits, and articles.

12. Flat tube: Use an instrument car to flatten one end of the tube mouth. The flat mouth is even, without gaps and burrs, and meets the requirements; handle with care to avoid pits, pits, pits, and scraps.

13. Roll up the corners: Use a lathe to roll the bulging corners of the bulged liner to meet the size requirements, handle it gently, and avoid pits, pits, pits, and scraps.

14. Flat top of the inner tank: Use an instrument car to have a uniform flat mouth, no gaps or burrs, and meet the requirements; handle with care to avoid pits, pits, pits, and scraps.

15. Thread rolling: Use a special threading machine, requiring attention, adjust the depth of the thread to meet the size requirements; handle with care to avoid pits, pits, pits, and scraps.

16. Washing and drying: Clean and dry the inner tank and outer shell; handle with care to avoid pits, pits, pits, and scraps.

17. Check knocking pits: check whether the inner tank and outer shell are qualified. If there are pits and pits, knock them flat to meet the requirements, and handle them gently.

18. Butt welding: butt welding the inner tank and the inner bottom, and the welding seam is required to be smooth, without loopholes, and without pits.

19. Water test and leak detection: Inflate the butt-welded inner tank to test the water, whether there is any loophole in the welded seam, and it is qualified if it does not leak.

20. Matching cup mouth: put the inner tank and outer shell together, and the cup mouth is flat; handle gently to avoid pits, pits, pits, and scraps.

21. Weld bottom of the weld: It is required to ensure that the bottom of the weld is penetrated and smooth, without bumps, weld bumps and missing weld points.

22. Spot welding: spot welding getter in the midsole. Note that the getter on spot welding must be vacuumed within 24 hours to achieve a good effect, otherwise it will be invalid.

23. Press the midsole: Press the welded cup onto the midsole where the spot welded getter is applied, and the pressure is even with the bottom.

24. Inspection of the bottom of the welded joint: inspect the cup with the well-welded bottom, and pick out whether there are missing welds, bad cup welds or other bad reasons.

25. Vacuuming: No-tail vacuuming, strictly in accordance with the vacuuming operation standard.

26. Temperature measurement: check whether the cup is vacuum, and pick out the non-vacuum cup.

27. Electrolysis: send to the outside electrolysis, the electrolysis in the cup is required to be evenly bright, without watermark and yellow dots.

28. Polishing: The cup shell is required to be polished delicately and with orderly lines, the cup mouth is smooth and bright, and there should be no obvious wire drawing, scratches, black wires, pits, and polishing paste residue.

29. Inspection and polishing: whether the polished cup meets the requirements, the bad ones should be polished again, and the good ones flow to the next process.

30. Press the outsole: Press the outsole on the polished cup, and it is required to be flattened.

31. Spray paint: send out spray paint with the same color as the same, and the spray paint is required to be even and firm, and there should be no paint drop, pitting, etc.

32. Inspect the spray paint: Check whether the painted cup meets the spray paint requirements. If it is not good, it must be re-painted and polished. If it is good, it will flow to the next process.

33. Silk screen: The logo should be clearly printed on the silk screen as required. The logo, size, color, and position should be as samples. The silk screen label cannot be stuck in a plastic bag and is not easy to buckle with nails, so it must be baked in a drying tunnel after silk screen printing.

34. Packaging